Belt sanders with floor stand and Servo finishing stand – redefining robotic material finishing

Belt sanders with floor stand and servo finishing stand – redefining robotic material finishing

The floor standing unit for part to tool applications can be easily integrated into robot cells. Unit provides a solution for automating belt sanding operations and precision finishing.

- Control of process and improved consistency

- Control of force, pattern, abrasive changes.

- High durability of electric motors allows continued operation

| Model | Function | Power | Speed (RPM) |

|---|---|---|---|

| EBS3k-FW | Dual wheel polishing stand | 3700 W | 1700 |

| EBS3k-FDL | Dual-wheel belt sanding stand | 3700 W | 1700 |

| EBS3k-C | Sanding stand with programmable compliance control | 3700 W | 1700 |

| EBS3k-DB | Stand dual belt sander | 3700 W | 1700 |

| EBS7k-H | Heavy-duty belt sanding stand | 7500 W | 1700 |

| BS800 BSA400 BSA800 | Small belt sander (EOAT) Mini Belt sander for narrow corners Belt sander for aggressive material removal | 1250 W 500 W 1250 W | 3000 16000 3000 |

EBS3k-FW Dual-wheel polishing stand

| Max force | x N |

| Power | 3700 W |

| Speed | 1700 RPM |

| Flap wheels | diameter 254-381 mm width 25,4-76 mm arbor whole diameter 25,4 mm |

| Weight | 616 kg |

| Dimensions | 833 mm x 747 mm x 1670 mm |

- Excellent access allows a robot to easily manipulate parts

- Allows installation of two different kinds of flap wheels

- The finishing stand has a high-torque servo motor

- Precise force and speed control

- Passive force control

- Dust collector

- An optional high-precision grinding wheel diameter detection system

EBS3k-FDL Dual-wheel polishing stand

| Recommended force | 49-174 N |

| Power | 3700 W |

| Speed | 1700 RPM |

| Belt | 50 x 2667 mm |

| Weight | 492 kg |

| Dimensions | 1500 mm x 925 mm x 1610 mm |

- Suitable for precision sanding and moderate material removal

- Servo belt stand

- Automatic compliance force control system

- Precise force and speed control

- Excellent access allows a robot to easily manipulate parts over the belt media

- Solid and vibration free construction

- User-friendly belt change, quick and easy

- Variable speed control

- Dual shafts allow multi-step sanding operations with different abrasive belt grits or even combining a belt operation on one side and an abrasive wheel on the other. Both units have the built-in ability to remotely adjust the force applied to the part, belt speed, and belt tracking during part processing, safely from outside the robot workcell.

- Dust collector

EBS3k-C Sanding stand with programmable compliance control

| Recommended force | 49-174 N |

| Power | 3700 W |

| Speed | 1700 RPM |

| Belt size | 50 mm x 3710 mm |

| Weight | 320 kg |

| Dimensions | 1338 mm x 810 mm x 1470 mm |

- Servo belt stand

- High-torque motor

- Programmable compliance force control system

- Rubber wheel assisted or direct belt sanding

- Easily removable contact wheels allow widths of xx cm plus a wide range of different rubber hardnesses

- Dust collector

EBS3k-DB Stand dual belt sander

| Recommended force | 49-174 N |

| Power | 3700 W |

| Speed | 1700 RPM |

| Belt size | 50 mm x 3710 mm |

| Weight | 385 kg |

| Dimensions | 1338 mm x 925 mm x 1610 mm |

- High torque servo motor

- Two sanding belts for rapid switching

- Accurate belt media speed control

- Passive force control

- Excellent access allows a robot to easily manipulate parts over the belt media

- Easily removable contact wheels allow widths of 75-150 mm, a wide range of different rubber hardnesses: 60-75 A (Shore A); other options on request

- Dust collector

- Pneumatic belt tensioning

EBS7k-H Heavy-duty belt sanding stand

| Max force | x N |

| Power | 7500 W |

| Speed | 1700 RPM |

| Belt size | 100 mm x 3770 mm |

| Weight | 787 kg |

| Dimensions | 1299 x 934 x 1823 mm |

- If the application will require more torque, the EBS7k-H is the largest finishing stand in the series

- Ideal for rough sanding and high material removal

- Perfect for large area machining

- Dust collector

BS800 Mini Belt sander for finishing

| Max force | 60 N |

| Speed | 3000 RPM |

| Belt size | 20 mm x 914 mm |

| Weight | 8,6 kg |

| Dimensions | 473 mm x 167,5 mm x 180 mm |

| Spindle pressure | 6 bar |

| Air consumption | 14 l/s |

- Ideal for stable linear grinding on long, straight sections

- Solution for fine finishing weld seam even scratches

- Adaptive compliance

- Simplified path programming

- High removal capacity

- Pneumatic motor

- Side and wrist mount

- Easy robot integration

- Controlled axial motion ensures stable results even with varying burr heights

- Maintenance-friendly design

- Dust collection system

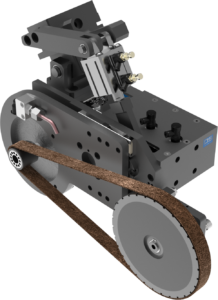

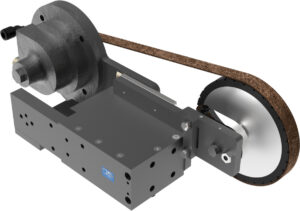

bsa400 MINI BELT SANDER

| Compliant stroke | Unidirectional 8° |

| Compliance force | 2,6-6,5 N |

| Spindle pressure Compliance Pressure | 6 bar 2-5 bar |

| Power | N/A |

| Speed | 16000 RPM |

| Air consumption | 10 l/s |

| Weight | 3 kg |

| Dimensions Belt size | 338 mm x 110 mm x 104 mm 20 mm x 520 mm |

- Compact EOAT belt sander for robotic finishing

- Pneumatic drive for smooth, controllable sanding

- Built-in compliance for delicate edge finishing and deburring

- Optimized for small to medium robots and complex paths

- Compatible with ABSC4-RTH automatic belt change system

BSA800 Belt sander for agressive material removal

| Compliant stroke | 15 mm |

| Compliance force | 36,5-91 N |

| Spindle pressure | 6 bar |

| Power | 1250 W |

| Speed | 3000 RPM |

| Air consumption | 16 l/s |

| Weight | 14 kg |

| Belt size | 25,4 mm x 914 mm |

| Mounting | Mounting Compatible with both horizontal and vertical mounting positions |

| Dimensions | 473 mm x 187,5 mm x 293 mm |

- Heavy-duty EOAT belt sander

- High-power pneumatic motor for stable operation underload

- Reinforced structure for vibration-free sanding of large parts

- Designed for longer duty cycles and higher process forces

- Compatible with ABSC4-RTH automatic belt change system