Pneumatic deburring & grinding

A smart choice for manufacturers looking to improve finish quality, reduce cycle time and simplify programming. LC300B, PC600 and PC900 provide professional finish for various metal processing tasks. Whether precision compliance is required for delicate edge work (LC300B), compact swing motion for high-speed surface grinding (PC600), or powerful, wide-area material removal (PC900), each tool is engineered with a clear application in mind.

Together, they offer a flexible lineup for integrators and manufacturers. Each tool ensures reliable performance, easy robot path programming, and efficient air-powered operation across a wide range of part shapes and production environments.

Model Weight (kg) Tool holder (mm) Compliance Force (N) Speed (RPM) LC 300B 2,6 16 21-53 2500 PC 600 2,4 8 20-50 18000 PC 900 4 8 20-50 12000

LC 300B Pneumatic Finishing Tool

Technical data

Features

Downloads

Compliant stroke Axial 16 mm Compliance force 21-53 N Spindle pressure 6 bar Power 370 W Speed 2500 RPM Air consumption 1,8 l/s Weight 2,6 kg Tool holder Ø3 mm / Ø6 mm Mounting Mounting Compatible with both horizontal and vertical mounting positions Dimensions 210 mm x 100 mm x 107,5 mm

Robust finishing tool, low speed, high torque air tool with an axially floating spindle

Best suited when a higher compliance force-to-weight ratio is required

For lightweight robots or installation space is limited. Reduces load requirements for the robot arm

Fast installation and easy integration

Excellent solution for automated surface finishing and edge rounding

Low air and energy consumption. Ideal for smaller cells or limited infrastructure

Simplifies robot programming thanks to axial compliance motion

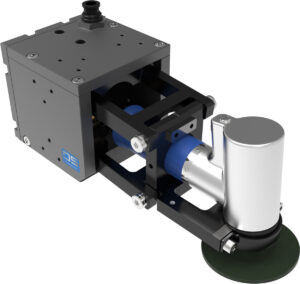

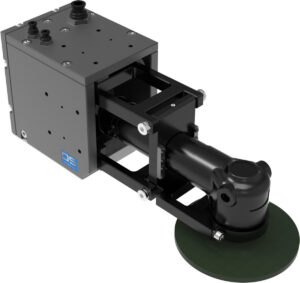

PC 600 Pneumatic Finishing Tool

Technical data

Features

Downloads

Compliant stroke 8 mm Compliance force 20-50 N Compliance pressure 2-5 bar Spindle pressure 6 bar Power 370 W Speed 18000 RPM Air consumption 2,5 l/s Weight 2,4 kg Grinding wheel/sanding disc 7,6 cm Mounting Robot arm or fixed station via screw and dowel holes, horizontally or vertically Dimensions 266 mm x 104 mm x 101 mm

Ideal for:

High-speed robotic deburring of machined, stamped or die-cast parts

Fine surface finishing on metals, plastics or composites

Edge rounding and contour grinding where consistent contact is critical

Compact tool for lightweight or mid-size robot arms

Pneumatic swing mechanism reduces risk of chatter or over-grinding

Precise robot pathing is not required, thanks to the compliance stroke and virtual offset logic

The tool maintains steady contact even over surface variations

Dual 4 mm quick connectors for air-actuated upward and downward swing control

Separate air inlets for spindle drive (6 mm) and compliance control (4 mm)

Requires ISO VG32 oil fog lubricationfor the spindle

Supports TCP setup using dimensions or four-point calibration

PC 900 Pneumatic Finishing Tool

Technical data

Features

Downloads

Compliant stroke 8 mm Compliance force 20-50 N Compliance pressure 2-5 bar Spindle pressure 6 bar Power 1300 W Speed 12000 RPM Air consumption 30 l/s Weight 4 kg Grinding wheel/sanding disc 12,7 cm Mounting Robot arm or stationery, horizontal, vertical-up or vertical-down Dimensions 266 mm x 104 mm x 101 mm

Edge rounding and smoothing before coating, painting or assembly

Automated sanding or polishing of flat or slightly contoured surfaces

Fast and aggressive grinding capability

Integrated swing mechanism allows smoother contact with complex or uneven surfaces

Adjustable and directional contact force by balancing air pressure to match different workpiece orientations and materials

Simplified robot programming

Compact design for automation cells makes it suitable for most industrial robot arms

Controlled compliance reduces the risk of overgrinding or tool wear

Easy maintenance, designed for continuous use with routine inspections and minimal downtime fixture